Unitized Glass Curtain Wall System Tlhahiso ea Kantle ea Lebota la Moralo oa Mabota mose ho Maoatle Ho Kenya Konteraka ea Kaho ea Deshion

Litšobotsi tsa lerako le kopaneng la likharetene

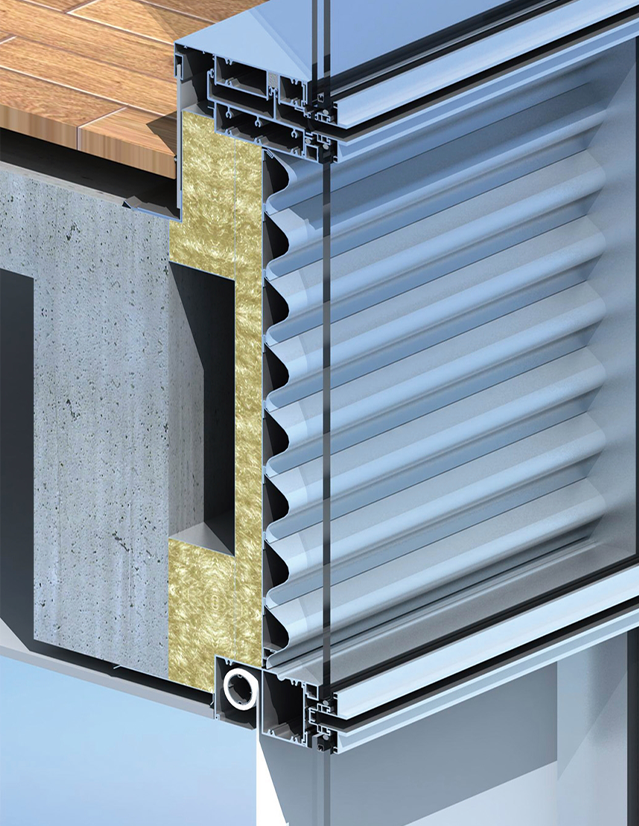

Lintlha tse ka sehloohong tse lebisang ho kheloha ha mohaho o ka sehloohong oa kaho ea sechaba ke: phoso ea kaho ea kaho ea sechaba, sebaka se sa tšoaneng sa bolulo, ho ba teng ha microseismic ka mor'a tšebeliso, ho senyeha ha tšisinyeho ea lefatše.Lerako le kopaneng la lesira le kentsoe ka har'a li-slots lipakeng tsa poleiti e 'ngoe le e' ngoe e haufi 'me le na le katoloso e ntle le matla a deformation.

E 'ngoe le e' ngoe ea poleiti ea lerako le kopaneng la lesira ke ntho e felletseng, kahoo phallo e lekanyelitsoeng ea karolo e 'ngoe le e' ngoe ea yuniti e nyane haholo, 'me bots'epehi ba poleiti bo ntse bo ka netefatsoa kamora ho atolosoa le ho seta bocha.

Kaha sehlopha sa sehlopha se bokelloa fekthering 'me se ka kenngoa ka ho toba ka mor'a hore se isoa setšeng, ntle le ho nka sebaka se sengata setšeng' me se ikarabella feela bakeng sa hoo e ka bang 30% ea lerako la lesira la thupa, le qobang stacking ea nako e telele le. ka katleho e fokotsa sekhahla sa tahlehelo ea lihlahisoa tse felileng.

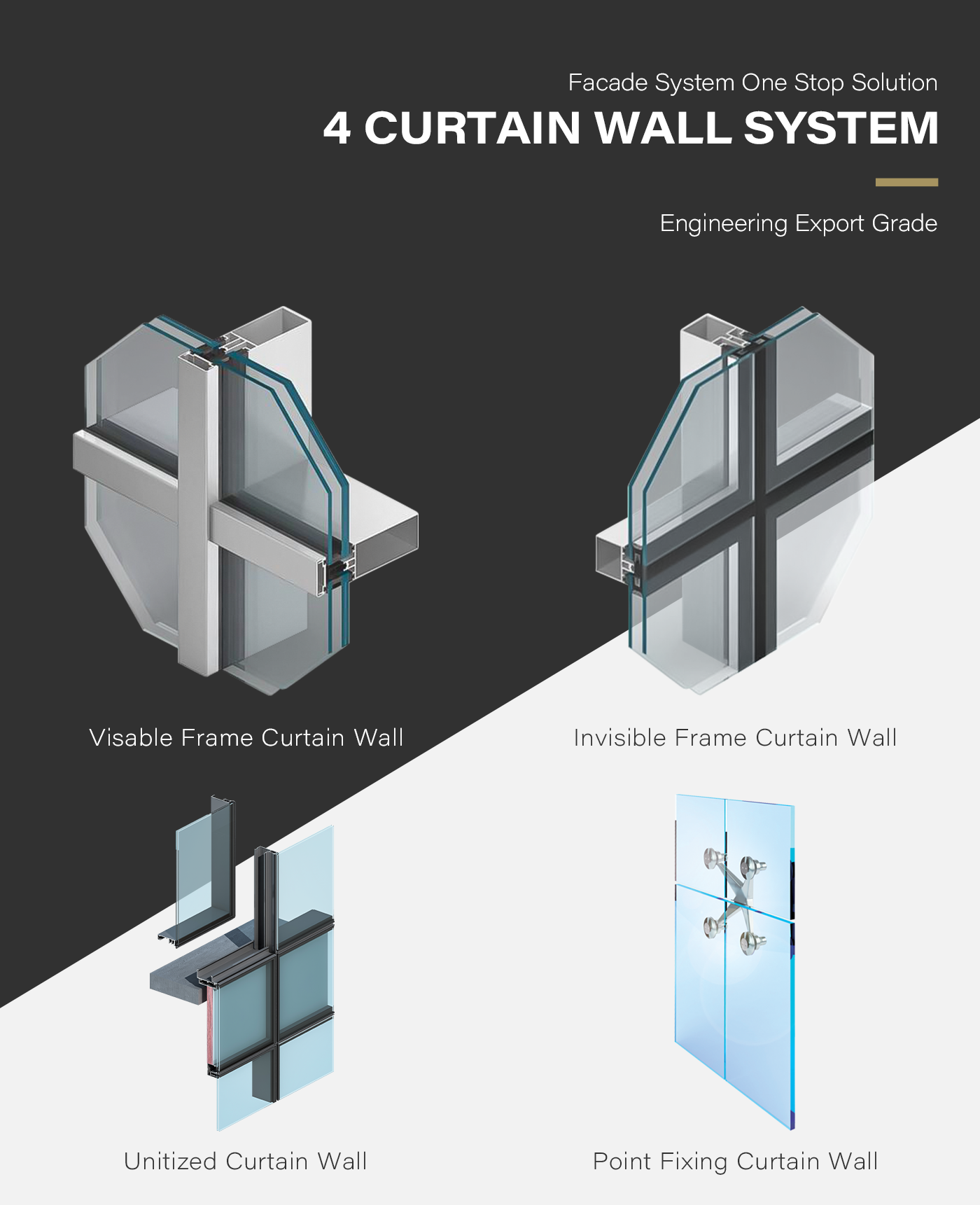

Litšobotsi tsa lerako la lesira la foreimi e kopaneng, lerako le kopaneng le patiloeng le patiloeng

| 01 | Li-unit plate kaofela li phethiloe ka har'a workshop ea feme ka nepo e phahameng ea kopano. |

| 02 | Lebelo la ho kenya ka potlako, nako e khutšoanyane ea kaho, ho bonolo ho sireletsa lihlahisoa tse felileng. |

| 03 | E ka hahoa ka mokhoa o lumellanang le mohaho o ka sehloohong oa mohaho oa sechaba, o leng molemo ho khutsufatsa nako eohle ea kaho. |

| 04 | Sebopeho se amohela molao-motheo oa ho senya mohato ka mohato, 'me tsamaiso ea drainage e behiloe ka hare, e nang le ts'ebetso e ntle ea ho thibela pula ea pula le ho kenella ha moea. |

| 05 | Likarolo tsa poleiti kaofela li tiisitsoe ka likhoele tse khethehileng tsa rabara tse thibelang botsofali, tse etsang hore lerako la likharetene le be le tšebetso ea ho itlhoekisa le hore bokaholimo bo se ke ba silafala. |

| 06 | Lipoleiti li kopantsoe ka ho kenngoa ha lipoleiti, ka matla a matla a seismic |

Diyuniti tse ikemetseng lerako la likhalase tsa khalase

| Lihlahisoa tse tloaelehileng | E ka kenngoa le ho qhaqhoa ka bolokolohi |

| Likarolo tsa sebopeho | Khalase haholo-holo e tlas'a khatello ea moea ke hook plate mahlakoreng a mane.Moralo oa sealant ea sebopeho o etsa hore sebopeho se be le ts'ebetso ea ts'ireletso habeli |

| Tšusumetso ea meralo | Mola o ka ntle oa pono o mokhuts'oane ebile o monate, o na le ho kenella hantle |

| Kopo | E ka fihlella poleiti e kholo ea karohano, e loketseng boema-fofane, holo ea lipontšo le moaho o mong o moholo |

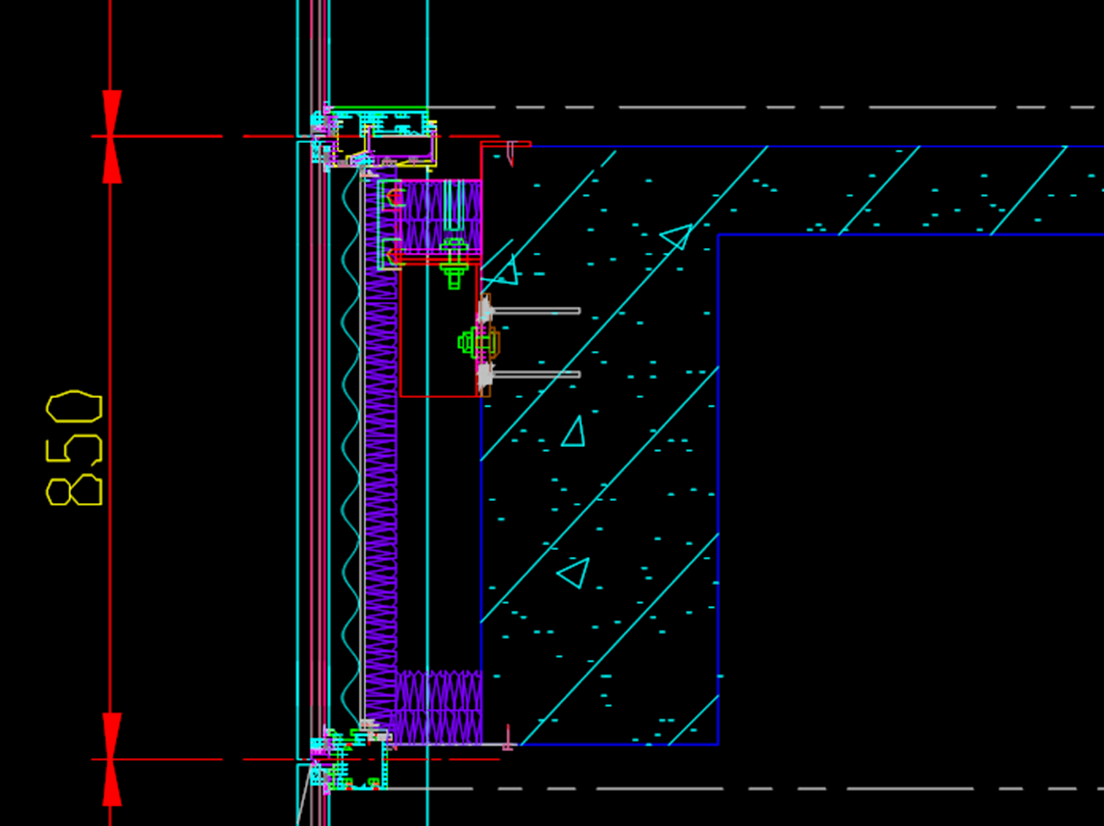

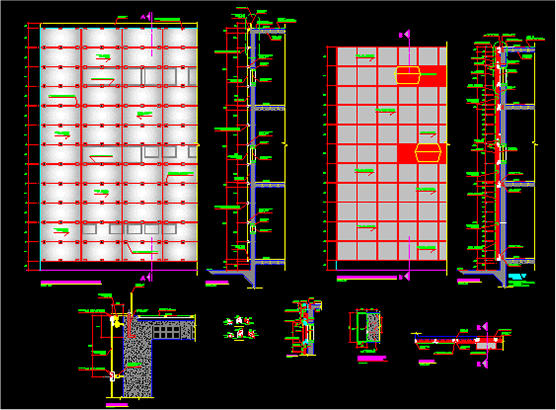

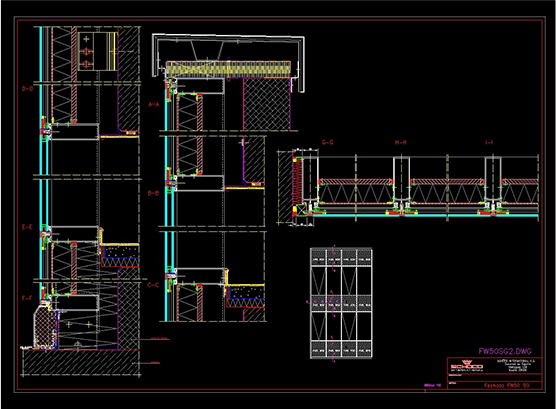

Molao-motheo oa ho qapa

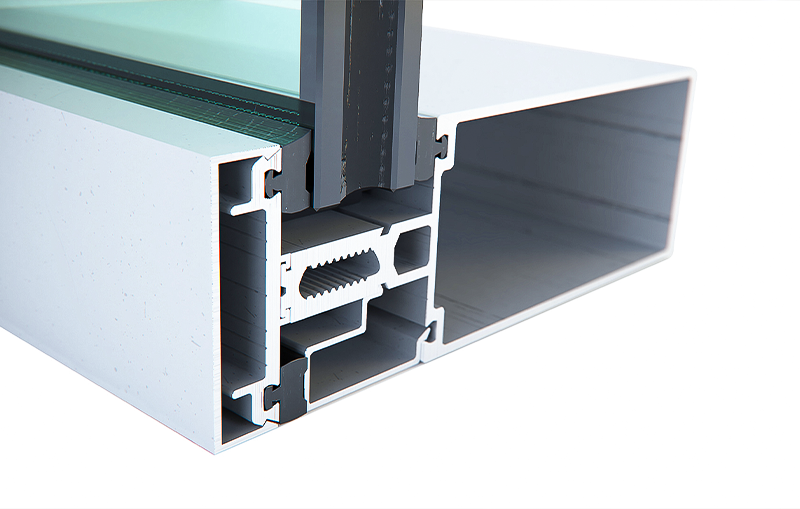

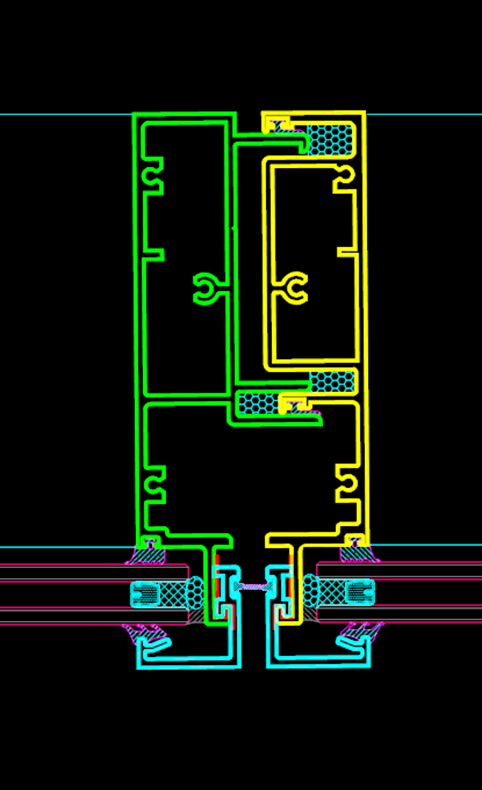

1. kopanya ntho e 'ngoe le e 'ngoe (mullion, foreimi e tšekaletseng) ka har'a foreimi ea karolo ea yuniti fekthering, 'me u kenye lerako la lerako la lerako (khalase, poleiti ea aluminium, lejoe, joalo-joalo) sebakeng se lumellanang sa foreime ea karolo ea yuniti ho etsa likarolo tsa likarolo.

2.Tsamaisa kopano ea karolo setšeng 'me u e lokise ka ho toba mohahong o moholo ka ho phahamisa.

3.Liforeimi tse ka holimo le tse ka tlaase (liforeimi tse ka ho le letšehali le tse ka ho le letona) tsa karolo e 'ngoe le e 'ngoe ea yuniti li kenngoa ho etsa molamu oa motsoako le ho tlatsa manonyeletso pakeng tsa likarolo tsa yuniti, qetellong li etsa lerako lohle la likharetene.

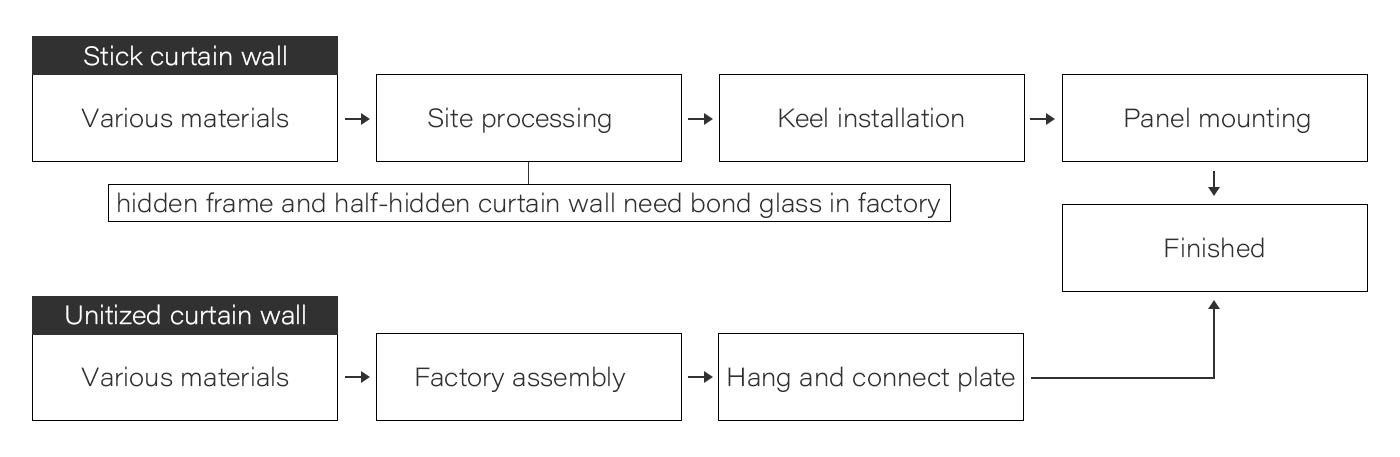

Chate e tsamaisanang le lerako la kharetene e kopantseng

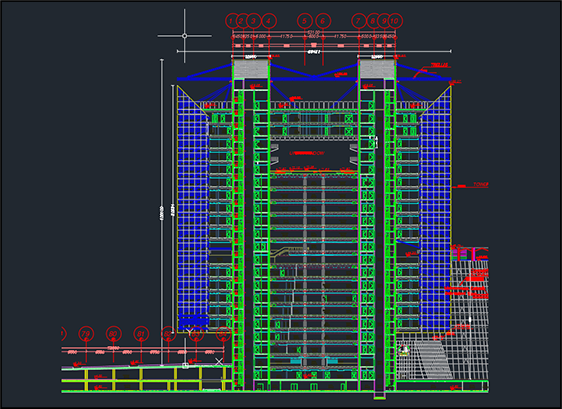

Ho phahamisa lerako le kopaneng

Ho kengoa lerako la likharetene

Ho phahamisa lerako le kopaneng

Ho kengoa lerako la likharetene

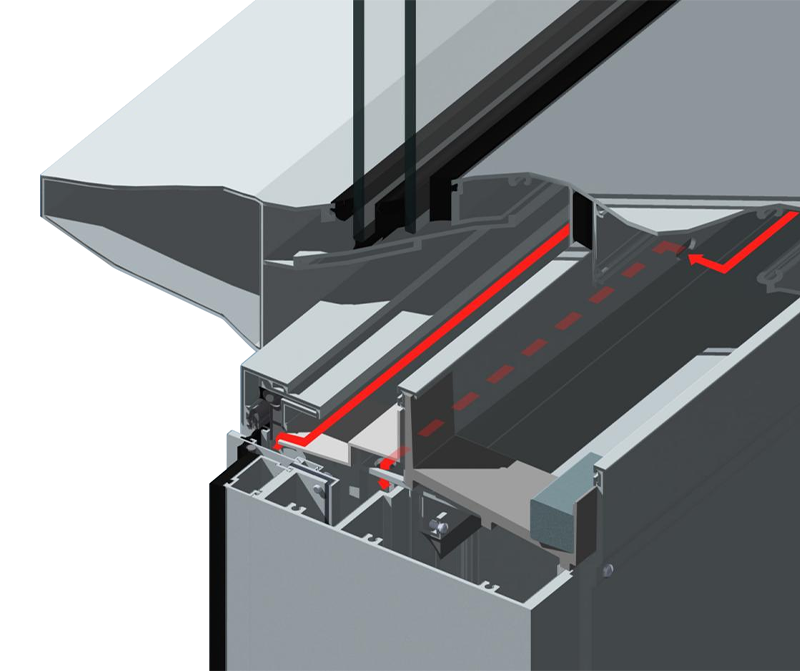

Tshebetso e sa keneleng metsi

Tataiso ea ho ntša metsi

*Lerako le kopaneng la lesira le amohela "molao-motheo oa isobaric", ts'ebetso e sa keneleng metsi e ntle

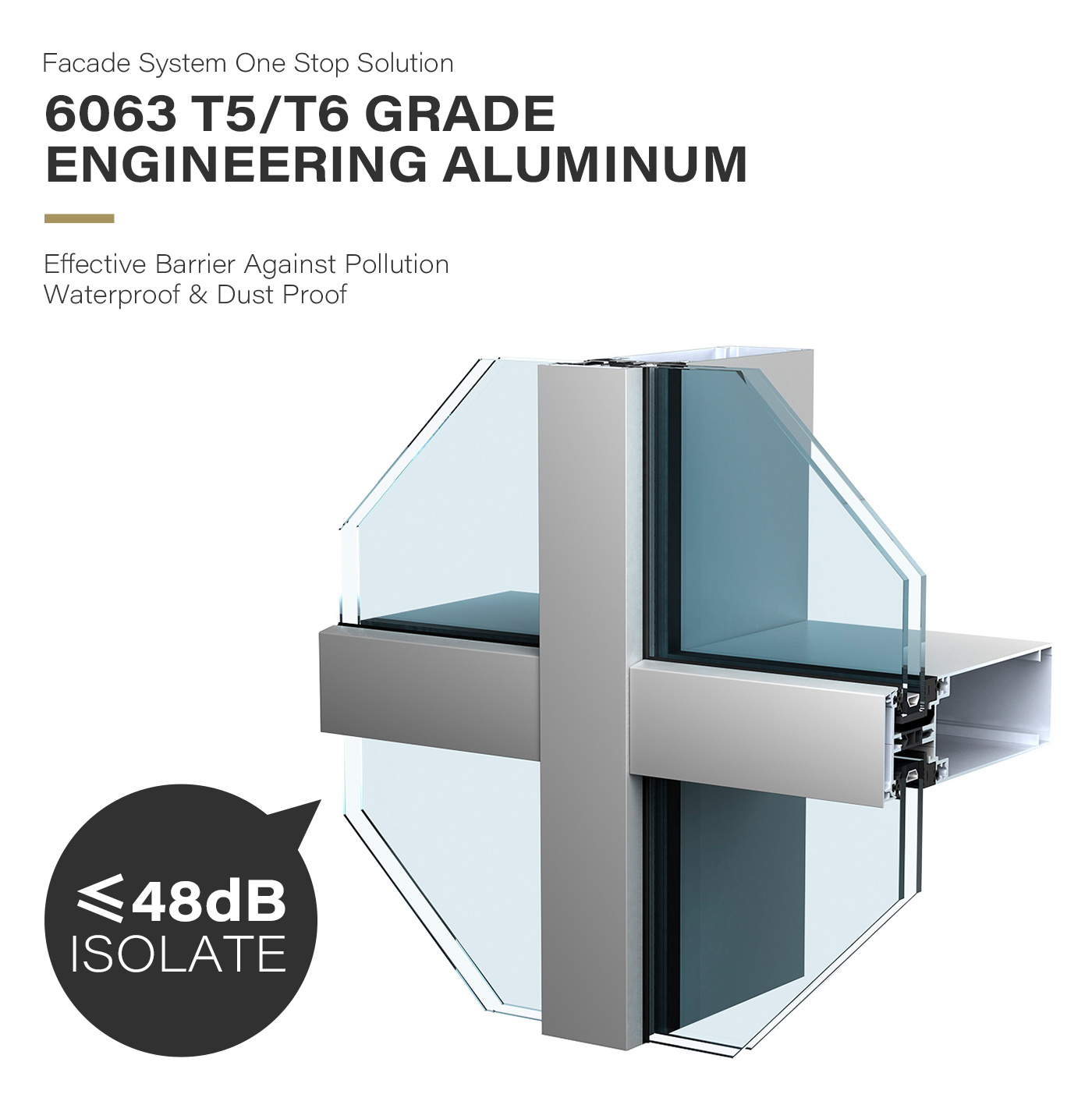

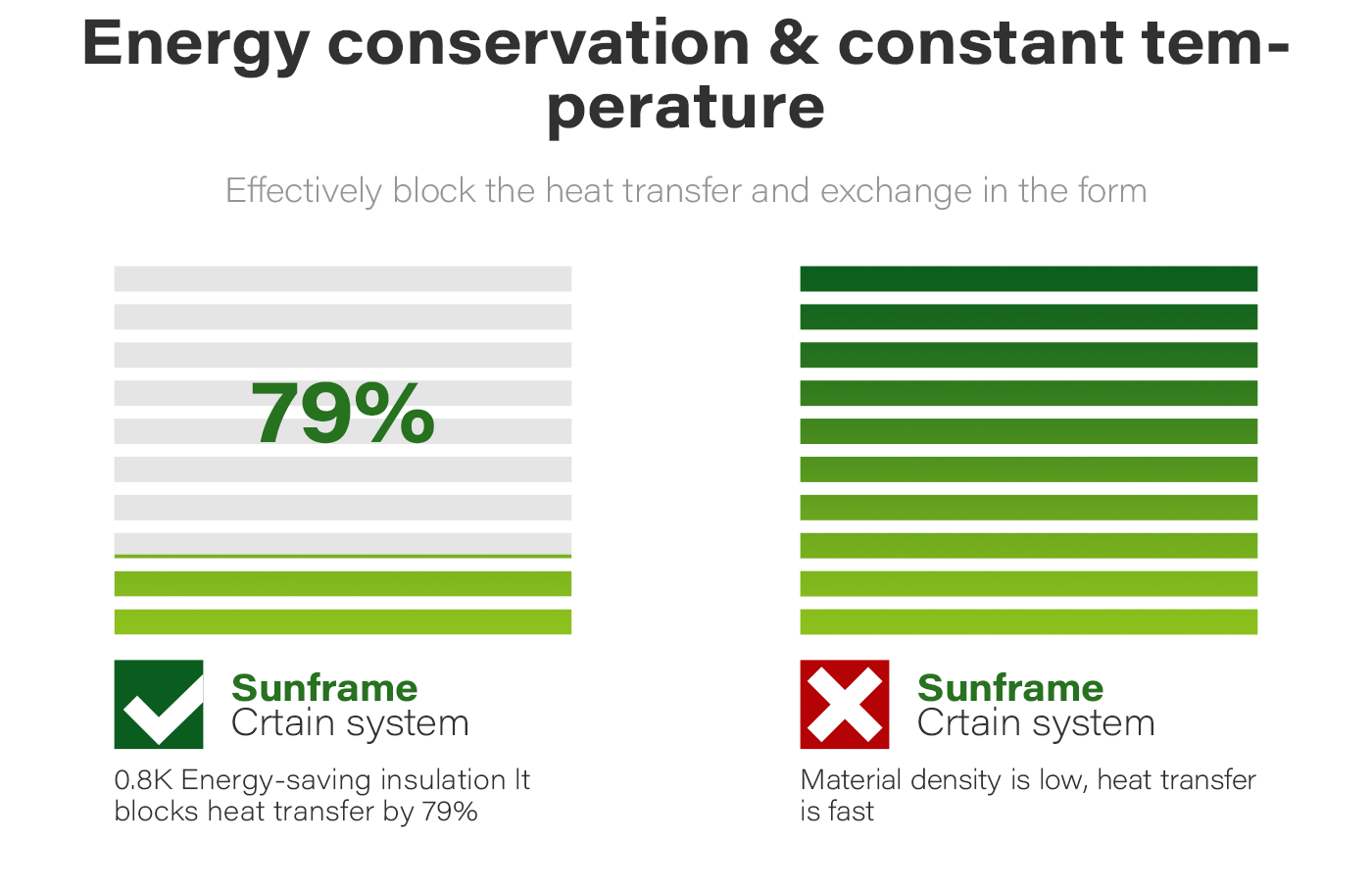

Moralo oa insulation oa lerako le kopaneng la lesira

Teko ea lerako le likhalase

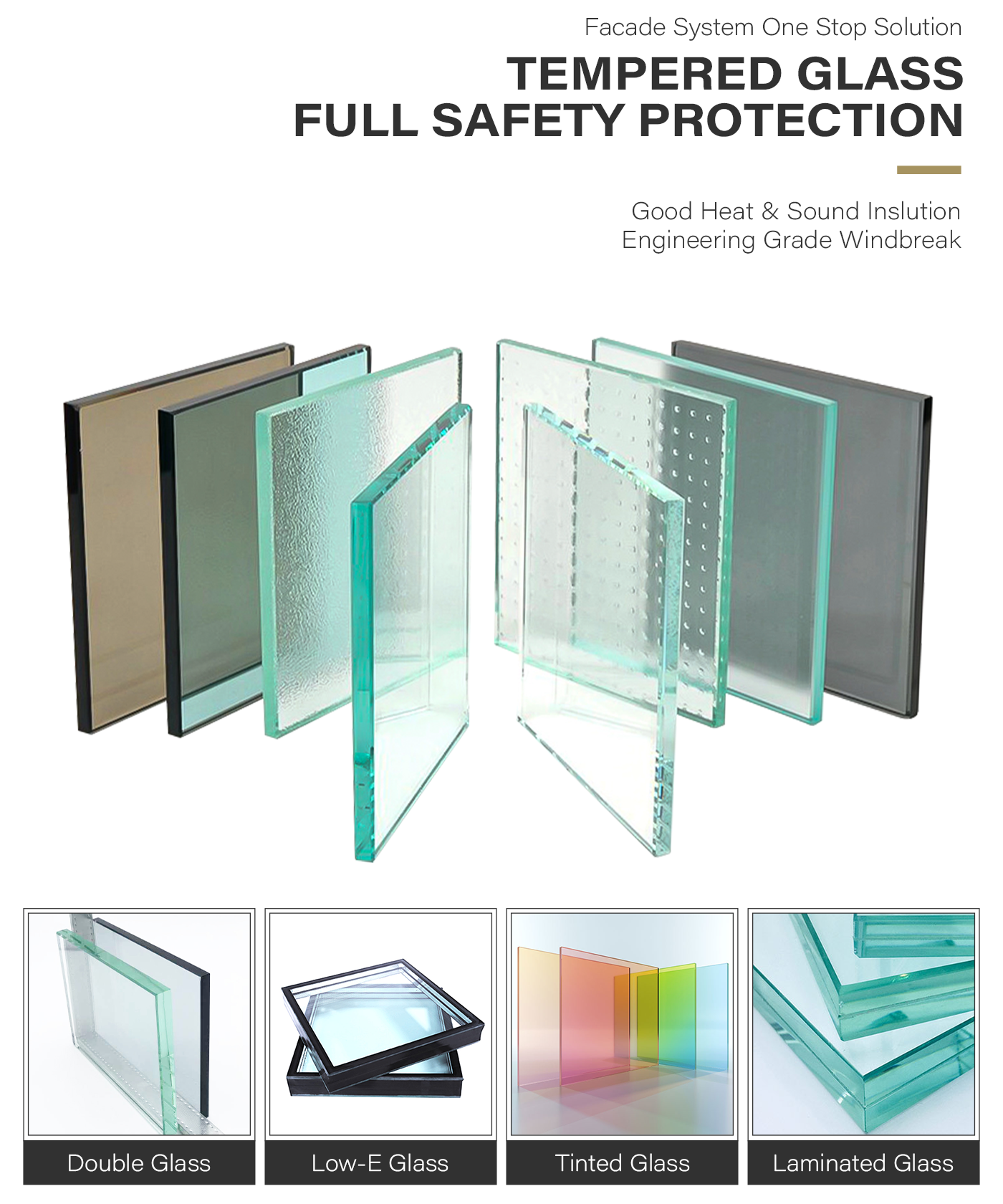

Lerako la lesira le nang le litlhoko tsa ts'ebetso ea mabone, ntlha ea phokotso ea phetisetso ha ea lokela ho ba ka tlase ho 0.45.Lerako la lesira le nang le litlhoko tsa khethollo ea mebala, index ea eona ea pono ea mebala ha ea lokela ho ba tlase ho Ra80

Lerako la lesira le tla khona ho tšehetsa boima ba lona le boima ba lisebelisoa tse fapa-fapaneng moralong, 'me le ka fetisetsoa ka botšepehi mohahong o ka sehloohong.

Ho kheloha ho hoholo ha setho se hatelletsoeng ka har'a nako lipheletsong tse peli tsa phanele e le 'ngoe tlas'a boima bo tloaelehileng ba lefu ha ea lokela ho feta 1/500 ea bolelele lipheletsong tse peli tsa phanele, mme e se fete 3mm.

Lerako leboteng le halefileng khalase lokela ho sebetswa ka ho qoelisa chesang.Phekolo ea mocheso oa bobeli, kalafo ea mocheso o kenang, kalafo ea detonation, "kamora kalafo e ka ba tlase ho 1/1000 ea sekhahla sa ho phatloha" hangata e sebelisoa boenjiniere.

Ho paka le ho romella

Moralo o ikhethileng oa mahala

Re rala meaho e rarahaneng ea indasteri bakeng sa bareki ba sebelisang AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures(Xsteel) joalo-joalo.

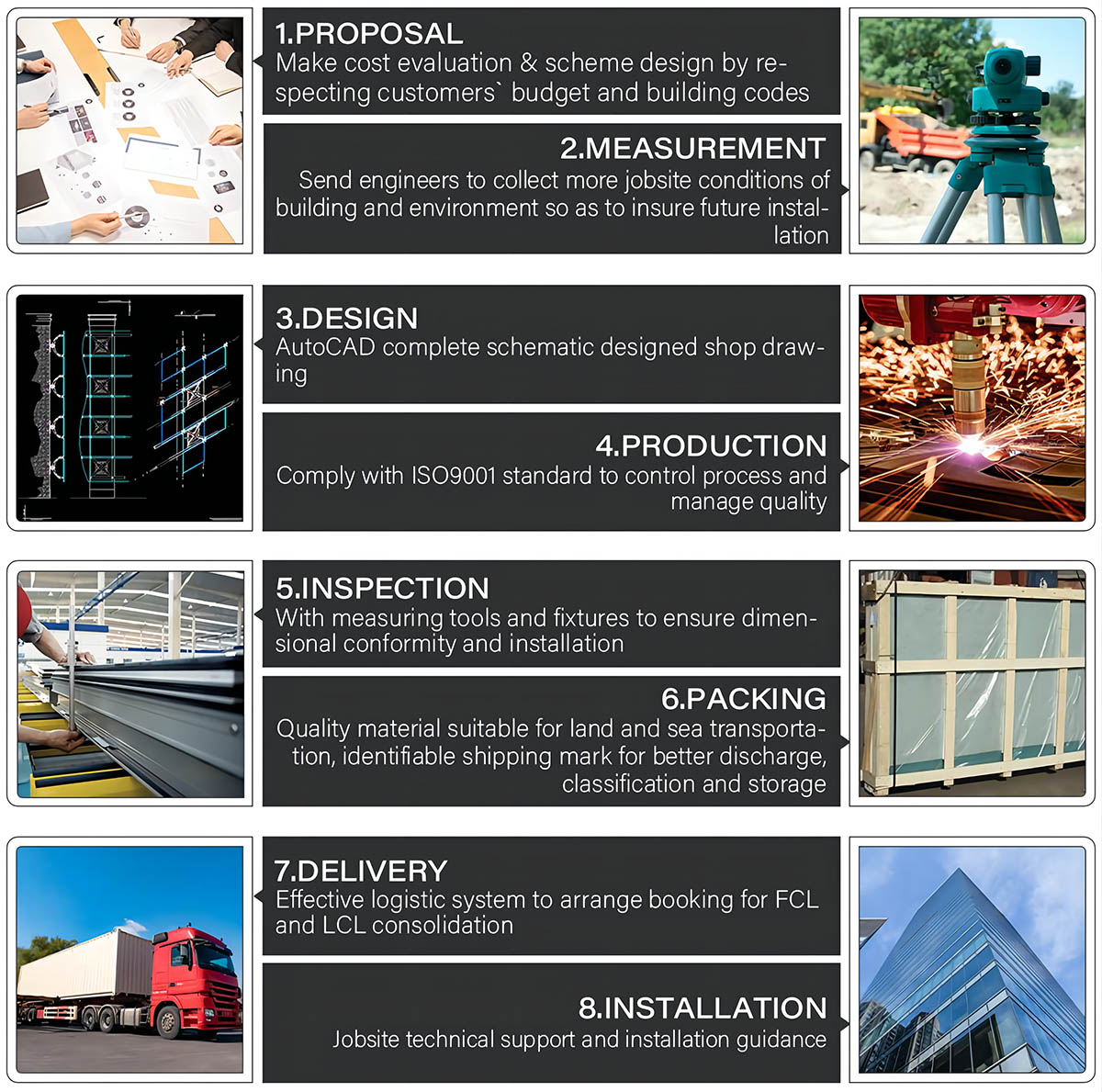

Mokhoa oa ho iketsetsa

Tlhahisoleseding ea Workshop Overview

Tshebetso ya Tshipi

Raw Material Zone 1

Aluminium alloy workshop

Raw Material Zone 2

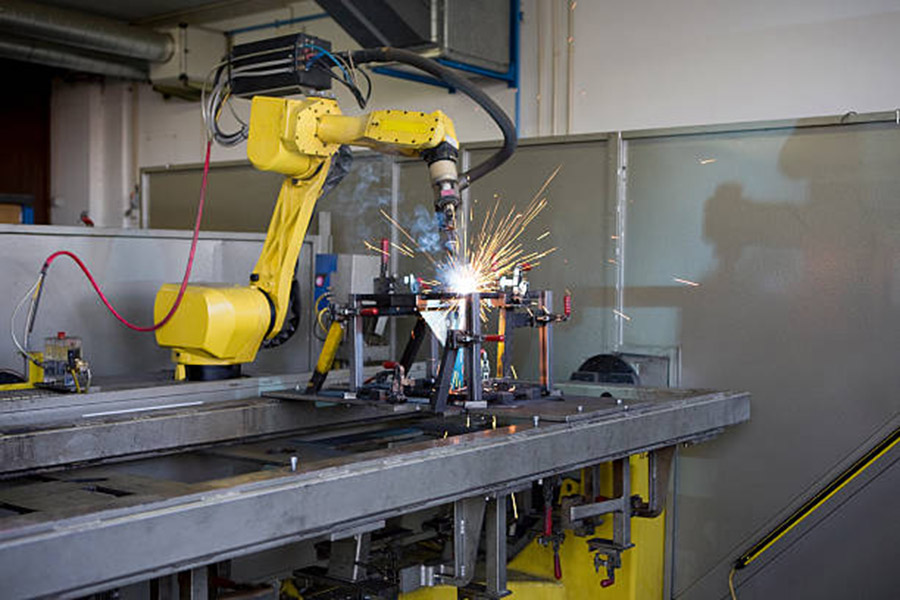

Mochini oa tjheseletsa oa liroboto o kentsoeng fekthering e ncha.

Automatic Spraying Area

Mechini e mengata ea ho itšeha

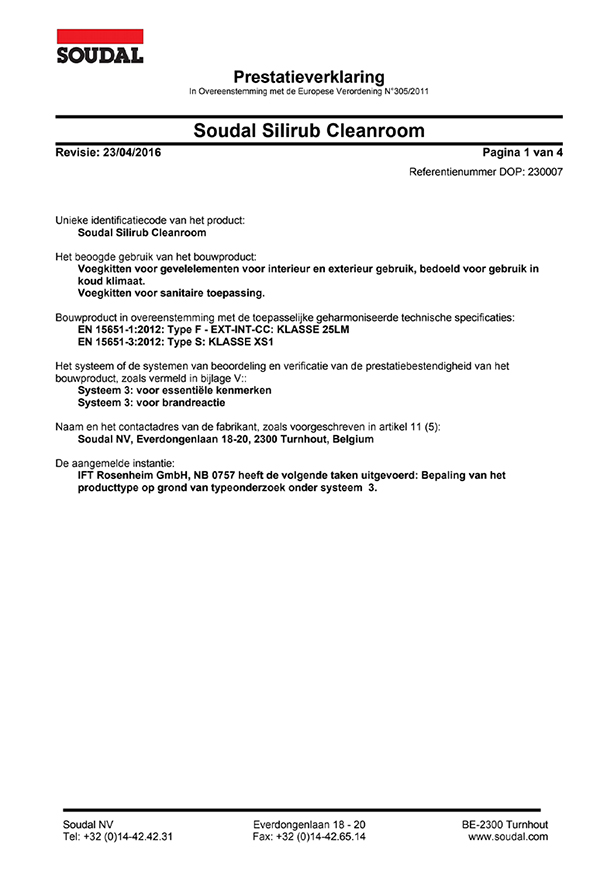

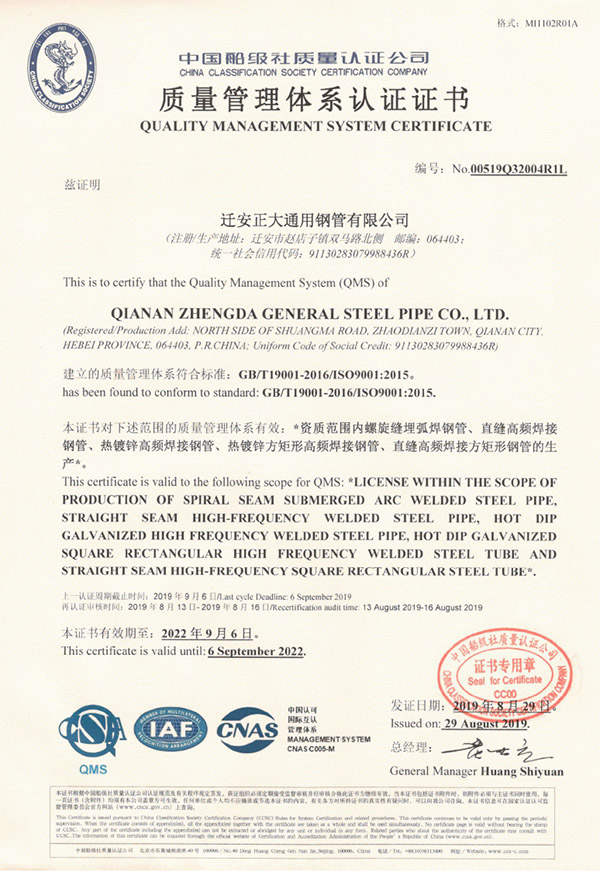

Bolaoli ba setifikeiti

Khamphani ea koporasi

LBH

1.Nako ea hau ea tlhahiso ke efe?

Matsatsi a 38-45 a ipapisitse le tefo e tlase e amohetsoeng le setšoantšo sa lebenkele se saennoeng

2. Ke eng e etsang hore lihlahisoa tsa hau li fapane le mofani oa thepa e mong?

Taolo ea boleng bo tiileng le theko ea tlholisano haholo hammoho le thekiso ea litsebi le lits'ebeletso tsa boenjiniere ba ho kenya.

3. U fane ka tiisetso efe ea boleng 'me u laola boleng joang?

E thehile mokhoa oa ho lekola lihlahisoa ka mekhahlelo eohle ea ts'ebetso ea tlhahiso - lisebelisoa tse tala, lisebelisoa tsa ts'ebetso, lisebelisoa tse netefalitsoeng kapa tse lekiloeng, thepa e felileng, jj.

4. Mokhoa oa ho fumana mantsoe a nepahetseng?

Haeba o ka fana ka lintlha tse latelang tsa morero, re khona ho u fa khotheishene e nepahetseng.

Khoutu ea moralo/ maemo a moralo

Boemo ba kholomo

Lebelo le phahameng la moea

Mojaro oa litšisinyeho tsa lefatše

Lebelo le phahameng la lehloa

Boholo ba pula